PICKLING FOR STAINLESS STEEL

With pickling, the oxides of the welds are removed.

Pickling is mainly used in the production cycle of stainless steel products to clean them of rust, calamine and processing residues, or as a cleaning and activation cycle before surface coatings such as painting, anodizing, passivation, chrome plating and nickel plating.

Pickling is a chemical treatment that allows you to remove surface layers of a material. The chemical pickling process is obtained through the use of acidic or alkaline solutions based on the metal to be treated. The pickling of metals is necessary in order to remove post-welding oxides or oxidation resulting from corrosive phenomena such as rust on iron or other slag on the surface of metals. For some metals, chemical pickling precedes painting to make the surface grip.

The pickling process can take place through three different techniques: mechanical pickling, chemical pickling and electrolytic or electrochemical pickling.

- Mechanical pickling involves the mechanical removal of impurities present on the surface of metals by abrasion, it is the most rudimentary technique not applicable on the noblest metals (such as stainless steel) where it can even become the main cause of future corrosion.

- Chemical pickling is carried out using spray, brush or immersion pickling agents by putting the surfaces in contact with ad hoc chemical solutions.

- Electrolytic or electrochemical pickling involves the use of chemical solutions together with the supply of electric current with a suitable waveform, which optimizes and speeds up the treatment of the metal, in an anode / cathode electrochemical system.

The pickling agent is the chemical solution that allows to treat metals by removing oxidation and impurities from surfaces. For the chemical pickling of metals, specific products are used based on the metal to be treated. The pickling agent for stainless steel was initially carried out with nitric and hydrofluoric acid making the pickling of stainless steel a difficult process. Delmet has patented systems and chemicals that allow stainless steel to be pickled instantly and through non-hazardous chemicals. Pickling for aluminum can be carried out hot or cold, while for copper and brass a pickling cycle is normally used which allows chemical brightening. The pickling agent for iron is usually acid-based but also in this case there are solutions with a reduced environmental impact.

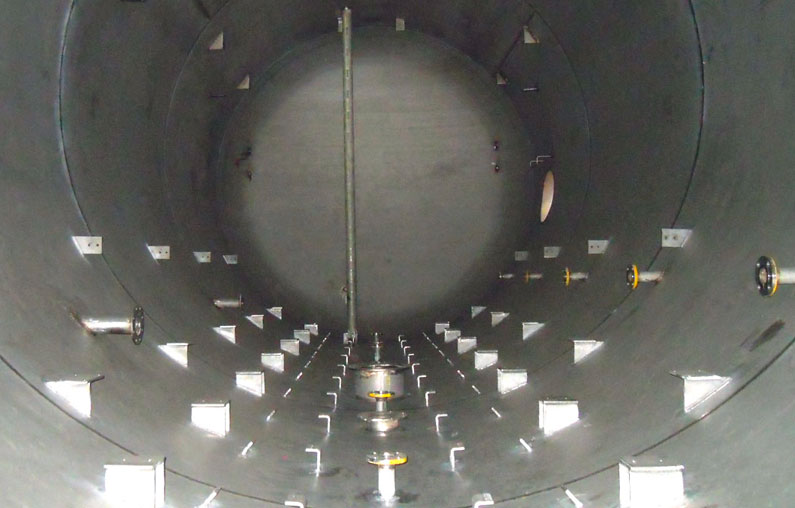

Chemical plants for stainless steel pickling

The machines and systems patented by Demet for the pickling of metals allow you to carry out treatments on metals instantly and independently, checking the result of chemical treatments in total safety. These systems are dedicated to those who handle stainless steel, in sectors such as food, pharmaceuticals, nautical, medical, energy, oil & gas. The stainless steel pickling systems allow you to manage the complete cycle: degreasing, decontamination, deoxidation, passivation, electropolishing, marking, burnishing. We design and manufacture chemical plants dedicated to the pickling of metals which can be manual or automatic.

The stainless steel pickling systems designed and customized by Delmet are able to induce the passivation process in safety and respect for the environment. The pickling treatment can be carried out in chemical or electrochemical mode. Chemical pickling plants are designed to pickle mainly stainless steel, copper and brass.

Delmet Pickling Quality

CERTIFICATIONS

• ISO 9001

• ISO 14001

CONTRACT PICKLING PROCESSING

For those who need to outsource the stainless steel pickling treatment, Delmet has state-of-the-art systems and products, which include immersion and spray techniques: a final control protocol ensures success.

PICKLING PLANTS

Delmet studies, designs and manufactures manual and automatic steel pickling systems. As with passivation, pickling plants also use immersion or spray techniques.

Solutions without limits

for the surface treatment of stainless steel

Electrolytic deoxidation of metals

Delmet Srl

Via Gera, 76 - 20060 Gessate (MI)

Italy